In this article, I summarize some points from a lecture that I gave at Hong Kong University in 2014; it drew on a blog I wrote in 2013. I repeat some of the ideas from that blog here because I believe they are critically important for world-class companies.

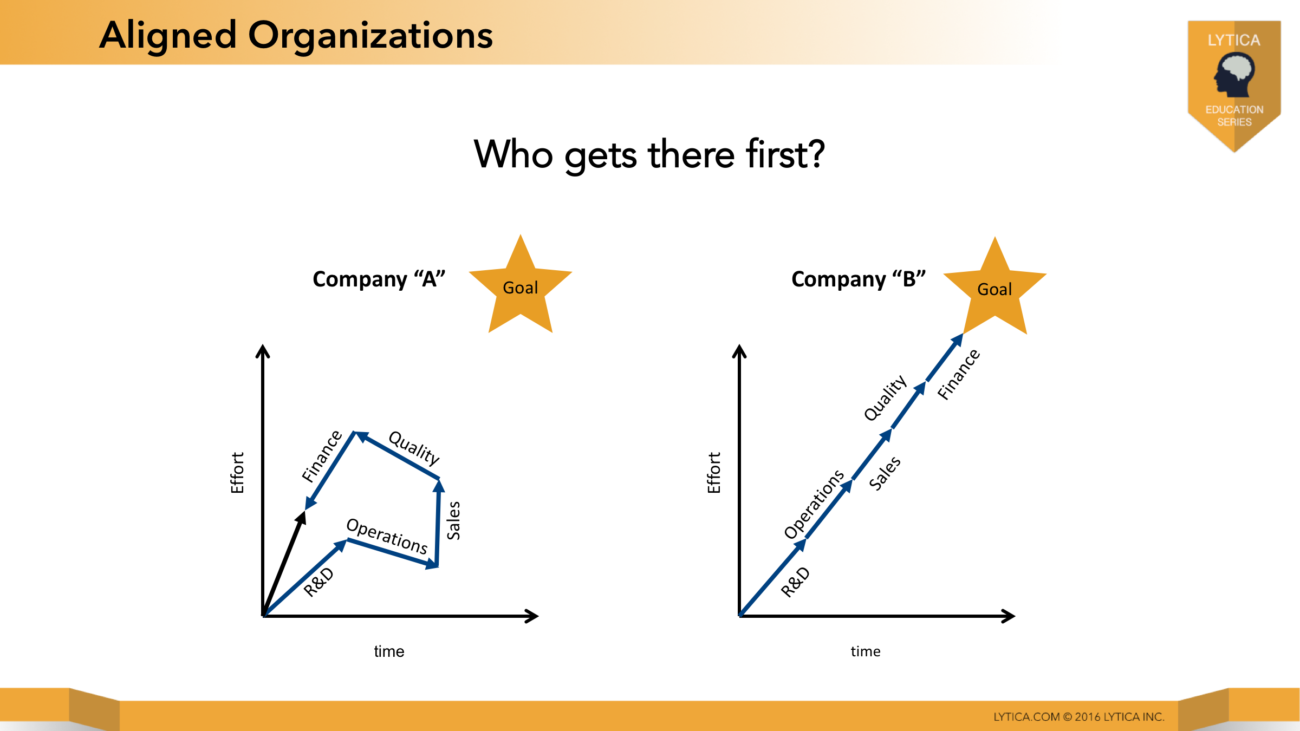

I was focused on supply base design, recognizing the key role that designers play in establishing the supply chain. Once a designer has selected a supplier or component, supply chain professionals are constrained; the designers set boundary conditions with their choices that often restrict optimal, total cost supply chain design. Given this, it’s important that designers be educated in supply chain matters so that they align with your supply chain priorities just as you must align with theirs. Your priorities of cost, security of supply and compliance and theirs of fast time-to-market should not be in conflict. As shown in our education series diagram below, alignment within an organization is fundamental to success.

I have selected 8 key supply chain rules for designers. Following these rules would prevent many of the issues that I see in supply chains.

- Use your leverage for cost: Do not award design wins until production level pricing is found to be acceptable and agreed upon by the operations team. Until the design socket is awarded you have leverage that can impact the component pricing on new design as well as on components within products already in production. For major projects, why not leverage for price concessions on existing production components? Leveraging is critical for high IP content – sole-sourced devices such as FPGAs, chip sets and processors are good examples.

- Benchmark: Find out what the true production level market value of a component is before awarding the socket. Benchmark component prices before agreeing to pricing; tools such as IHS’ Component Price Benchmark or Lytica’s Freebenchmarking.com and Component Cost Estimator will do this. Getting the pricing right is critical on short lifecycle ODM products. One never knows when a competing product will come to market with features or price points that will put your product into a pricing war; you must be the low cost producer in your market space (functionality, quality, service, reliability, etc.).

- Multi-sourcing: Don`t create single points of failure in the supply chain by having only one manufacturer able to supply. In cases where you must single source, with components such as FPGAs for example, make sure a security of supply plan can be put in place to avoid supply disruptions. Alternate manufacturing sources also create leverage for better pricing. Specify at least two manufacturers, where possible, for all components in your design. Even when you specify more than one source, you may be at risk if you don’t understand customer concentration. If one customer is buying 90 percent of a component’s production and that company stops buying, your source is as good as dead. Don’t cheat and specify 5 percent versions as a second source for 10 percent ones. Focus on a few component manufacturers to allow concentration of your spending for leverage. Make sure the manufacturer deserves your business by being service-oriented, cost-effective and a reliable source with acceptable quality. Operations should know who meets these criteria. Surveys of Operations and Design about supplier performance are often useful in weeding out suppliers or manufacturers with marginal performance. NPI support is as important as production support. Finally, specify components to concentrate with as few values as possible in order to simplify operations management and create leverage. For example, don`t specify multiple decoupling capacitor values if one value will do.

- Thorough simulation: Be sure to simulate designs to work under all operating conditions of voltage, temperature and manufacturing tolerance. Make notes on the design file about the testing required to qualify a substitute component because, at some point, component engineering will need to find an alternate part. This greatly assists with component obsolescence or cost reduction substitutions and may allow substitution via a component engineering paper study rather than full emissions testing or re-simulation.

- Design for portability: Important but almost never discussed; design so that products can be moved from factory to factory, manufacturer to manufacturer or country to country with relative ease to avoid lock in. Don’t design in such a way that a very expensive tester is required in production if additional built in testing could eliminate the need. I am not recommending that manufacturing should be moving products from factory to factory, I am suggesting that your company will get better pricing if the supplier knows that your company could easily move to a competitor. Also, you save your company the cost of an expensive tester or other piece of manufacturing gear.

- Registration: Don’t get locked into a supply channel without your permission. Minimal or no engineering support from a distributor or representative can lead to a registration situation. Once your design is registered (with or without your knowledge), you have little price negotiation leverage. Know if you are being registered and ask for justification as to why. Stop doing business with any manufacturer or supplier who registers you without your approval.

- Select suppliers willing to share information:Today, manufacturers are under increased scrutiny for compliance with social norms and legal requirements everywhere they do business. Assurance of this requires that you get information about your supply chain. You need suppliers who are willing to share information with you so that you can assure your shareholders, customers and other stakeholders that you are in compliance. Environmental and social responsibility performance (RoHS, restrictions on conflict minerals, etc.) is crucial. In today’s economy the risk of supplier failure is higher. To be confident that your suppliers are going concerns you should make supplier risk assessment part of the BOM (bill of materials) scrub. There is a need for greater due diligence with suppliers. As a designer, you audit supplier compliance with design requirements; you need to make sure the supplier will cooperate on going concern and social responsibility verification as well.

- Ensure operations is engaged in NPI before you award design sockets: Operations should be doing a number of things for you as an extension of your design team. In fact, most of my other 7 rules can be performed by them under your co-ordination. To simplify their role with you consider insisting that they conduct a BOM Scrub which provides:

- Supplier and component de-risking

- Cost optimization during design phase

- Compliance due diligence

As mentioned at the onset, these concepts/rules are critically important for world-class companies. None of them are rocket-science but they all pass the common sense test. As a simple exercise, take these rules and use them as talking points at your next joint design/operations meeting. At the very least it will generate some excellent discussion and will expose any philosophical differences between the two teams.

Ken Bradley is the founder of Lytica Inc., a provider of supply chain analytics tools and Silecta Inc., a SCM Operations consultancy.